Retort Pouch

Retort packaging bags are a unique type of flexible packaging that can withstand high temperatures 121 ℃ and pressures, making them ideal for packaging ready-to-eat meals, soups, sauces, and other food products that require sterilization.

These bags are made from multiple layers of materials, each serving a specific purpose to ensure the product’s safety, shelf life, and integrity.

Here are the key features and benefits of retort packaging bags

Retort pouches features

Withstand 121℃ for 45min and 134℃ for 5min

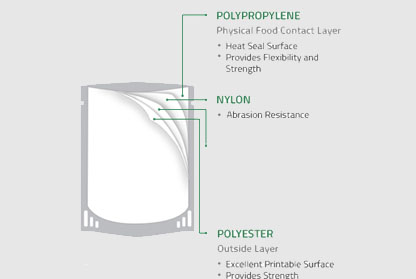

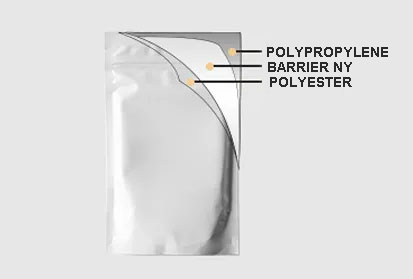

Multi-layer Structure

retort bags are made of three or more layers. It could be with or without aluminum foil, or Alxo PET

Heat Resistance

Designed to withstand 121℃ for 45min and 134℃ for 5min during the retort (sterilization) process

Barrier Properties

Excellent barrier against moisture, oxygen, and light, ensuring extended shelf life for the products inside

Hermetic Seal

Ensures the package is airtight, no leakage preventing contamination and preserving the freshness of the food.

Regular

Retort Pouch

Microwavable

Retort Pouch

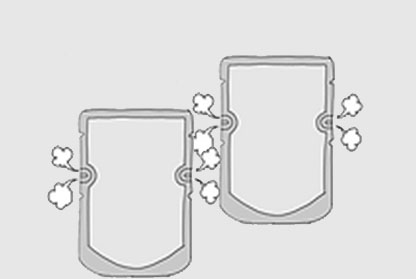

Auto Ventilation

Retort Pouch

Outside Layer: Polyester (PET)

Barrier Layer: Aluminum Foil (AL)

Abrasion Resistance Nylon (NY)

Inside Layer: Polypropylene (PP)

Outside Layer: High Barrier Polyester (PET)

Abrasion Resistance: Nylon (NY)

Inside Layer: Polypropylene (PP)

Built-in vents or valve mechanisms that automatically open to release excess steam during the retort process, then close to maintain a hermetic seal

Applications

Withstand 121℃ for 45min and 134℃ for 5min

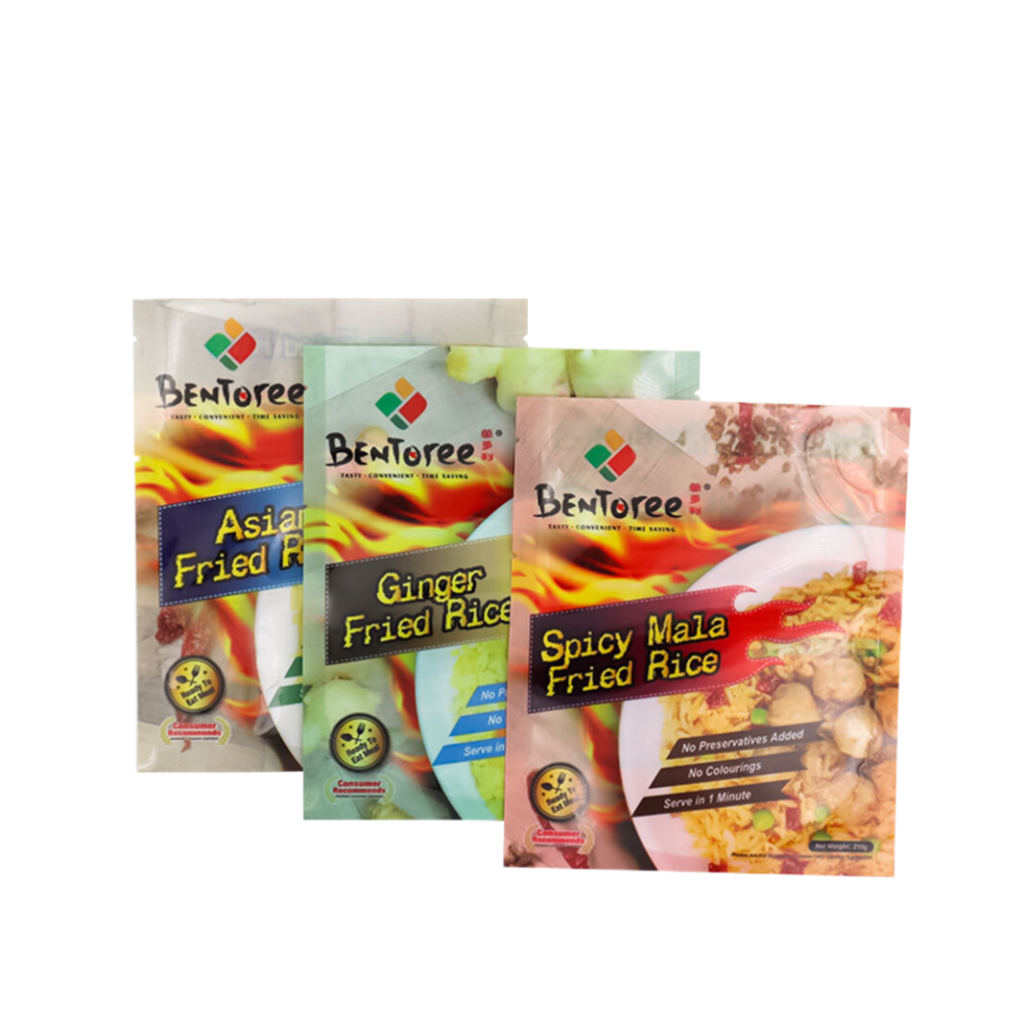

Ready-to-Eat Meals

Convenient packaging for meals that just need to be heated before consumption.

Soups and Sauces

Keeps liquids fresh and ready to serve only need cooking a while in the oven or boiling

Pet Food

Ideal for single-serving portions, maintaining freshness and nutrition of food

Medical and Nutritional Products

Used for packaging sterile medical foods and supplements.